Our Plastic Injection Molding South Carolina Plant

In 2001 JATCO expanded and acquired a new state of the art plastic injection molding South Carolina facility that would better serve the east coast customer base. Our South Carolina plastic injection molding facility offers the same services our west coast California facility presently does. With a presence in South Carolina we have been able to reduce shipment and delivery time, and cut down transportation costs for our east coast clients.

As a plastic mold manufacturer with over 50 years of global experience, we welcome your inquiries for any and all projects. Next time you are looking for a highly experienced and affordable plastic injection molding company near you give our South Carolina headquarters a call at 864-323-0588.

For directions to our JATCO plant in Greenwood South Carolina click here. You may also follow us on our GMB page for latest updates, operating hours and more.

Our experienced in-house engineers and industrial design, tooling and mechanical engineering specialists can help and evaluate your product and offer suggestions that can help you save time and money for your production needs. We not only manufacture plastic products, but we also help our customers out to obtain the most optimal output by working with them on a solution that will meet their customers needs and save them time and money!

We can help you with:

Get a quote today, by contacting Steven Ames, Director of Sales at 209-497-4290

Design and engineering – Work with our experienced in-house engineers and industrial design, tooling and mechanical engineering specialists who can develop virtually any new product.

Tooling – Jatco South Carolina team provides in-house tooling to support mold construction, mold maintenance and mold modifications. A fully equipped tooling facility has everything needed, including CNC machining centers, CNC EDM, automated grinding equipment and a full array of standard mold-making machinery.

Molding – Over 70 presses, from 28 to 1000 tons, and multi-component capability. All presses equipped with robotics, most with 3 axis servo robot capability to handle the most complex molding operations. Automated material handling, central drying and electronic monitoring.

Manufacturing – Jatco offers full, turn-key service, supported by a professional secondary operations department for assembly and decoration. We pride ourselves on our ability to “do it all,” including mechanical assembly, electric assembly, ultrasonic welding, pad printing, silk screening, packaging, hot stamping, warehousing and distribution.

Warehousing and distribution – With more than 210,000 square feet of indoor storage capacity, 10 dock doors and a dedicated staff to assist in shipping, Jatco moves your product via UPS, Fed Ex, truckload, LTL, air freight and ocean container to any location worldwide, when you need it.

Quality control – With services from incoming inspection to final dock audits, Jatco can customize a quality plan to suit the most detailed performance requirement.

For driving directions to our South Carolina plant click here.

About Jatco

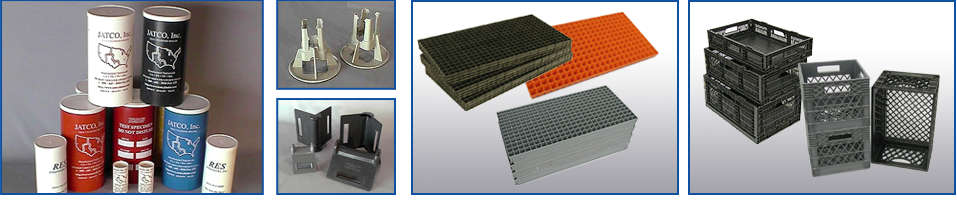

JATCO is a SF Bay Area plastics manufacturer who is knowns as a global leader in plastic injection molding. We are a one stop shop which offers plastics product (life) consulting, plastics design, plastics production, warehousing and distribution solutions for just about any project.

JATCO CONTACT INFORMATION

Our World Headquarters address is:

Jatco Incorporated

4801 Stoddard Road

Modesto, CA 95356 USA, U.S.A.

Tel: 209.497.4297

Fax: 510.4871880

Also visit our other sites (click below): TestCylinderMolds for test cylinders

Plantway for plant trays