Over

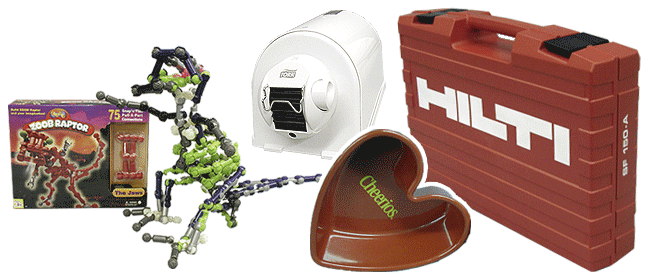

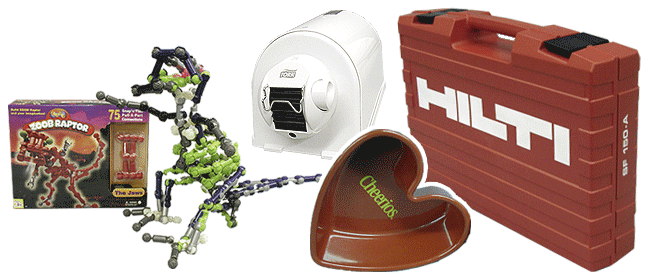

forty years of custom plastic injection molding experience with an amazing range of solutions for any plastic project.

Design and engineering

Design and engineering – Experienced in-house engineers and industrial design, tooling and mechanical engineering specialists can develop virtually any new product.

Tooling – Jatco provides in-house tooling to support mold construction, mold maintenance and mold modifications. A fully equipped tooling facility has everything needed, including CNC machining centers, CNC EDM, automated grinding equipment and a full array of standard mold-making machinery.

Plastic Injection Molding – Over 70 presses, from 28 to 1000 tons, and multi-component capability. All presses equipped with robotics, most with 3 axis servo robot capability to handle the most complex molding operations. Automated material handling, central drying and electronic monitoring.

Manufacturing – Jatco offers full, turn-key service, supported by a professional secondary operations department for assembly and decoration. We pride ourselves on our ability to “do it all,” including mechanical assembly, electric assembly, ultrasonic welding, pad printing, silk screening, packaging, hot stamping, warehousing and distribution.

Warehousing and distribution – With more than 210,000 square feet of indoor storage capacity, 10 dock doors and a dedicated staff to assist in shipping, Jatco moves your product via UPS, Fed Ex, truckload, LTL, air freight and ocean container to any location worldwide, when you need it.

Quality control – With services from incoming inspection to final dock audits, Jatco can customize a quality plan to suit the most detailed performance requirement.

ANAB CERTIFIED

Jatco is one of the few and rare plastic injection molding firms that is

ANAB accredited (ANSI-ASQ National Accreditation Board).

[button link=”https://www.jatco.com/get-a-quote-for-plastic-molding-projects/” type=”big”] Request a Quote[/button]